Evaluate your machine, test its usability and performance prior to any physical prototype. Give your product and development a head start by combining the mathematic dynamics of your machine and its 3D model for a realistic simulation. Get a free roadmap session now to achieve your digital prototype!

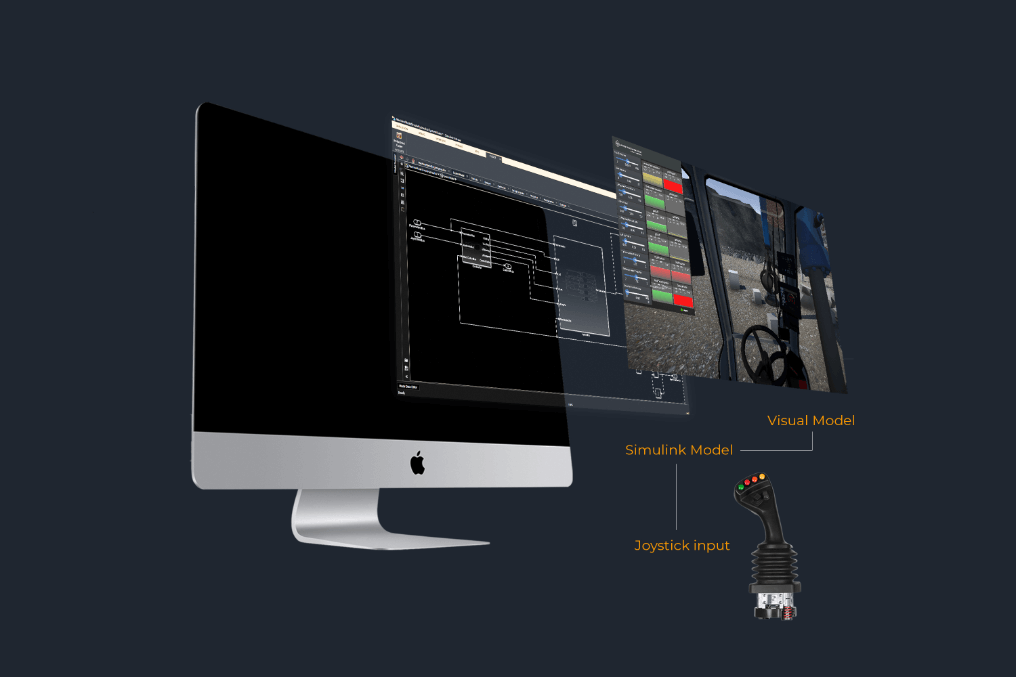

In collaboration, Elomatic and Devecto developed a method that links the 3D world with the physics model of a machinery creating a realistic simulation that is easily accessible and controlled with common hardware that you already have.

The method called The Link, connects the two models so that information flows both ways. By linking the dynamics model to the 3D model, both realistic visuals and authentic feeling are achieved in the digital prototype that can be used for testing and evaluation prior to building the physical prototype.

Cutting costs by minimizing physical prototypes

Faster testing and validation

Combining control and physical features with usability

Includes the whole life and soul of a machine, making it broadly applicable for R&D, marketing & sales, maintenance and training

One digital prototype for all departments brings consistency and savings

Develop new features and functionalities in the Digital Prototype

Get feedback from different user groups in advance

No expensive equipment and investments needed

The proof of concept presented here is an imaginary Terex Fuchs material handling machine. The control system, hydraulics and mechanics of the machine are modeled in Simulink. While the machine in virtual landscape is operating in Unity.

There is a dashboard that shows values from the machine model such as hydraulic pressures in cylinders. Parameters are adjustable in the Simulink model. Collisions and other interactions with the virtual environment can flow from Unity to the Simulink model.