24.6.2020 at 8:00 am GMT & 1:00 pm GMT

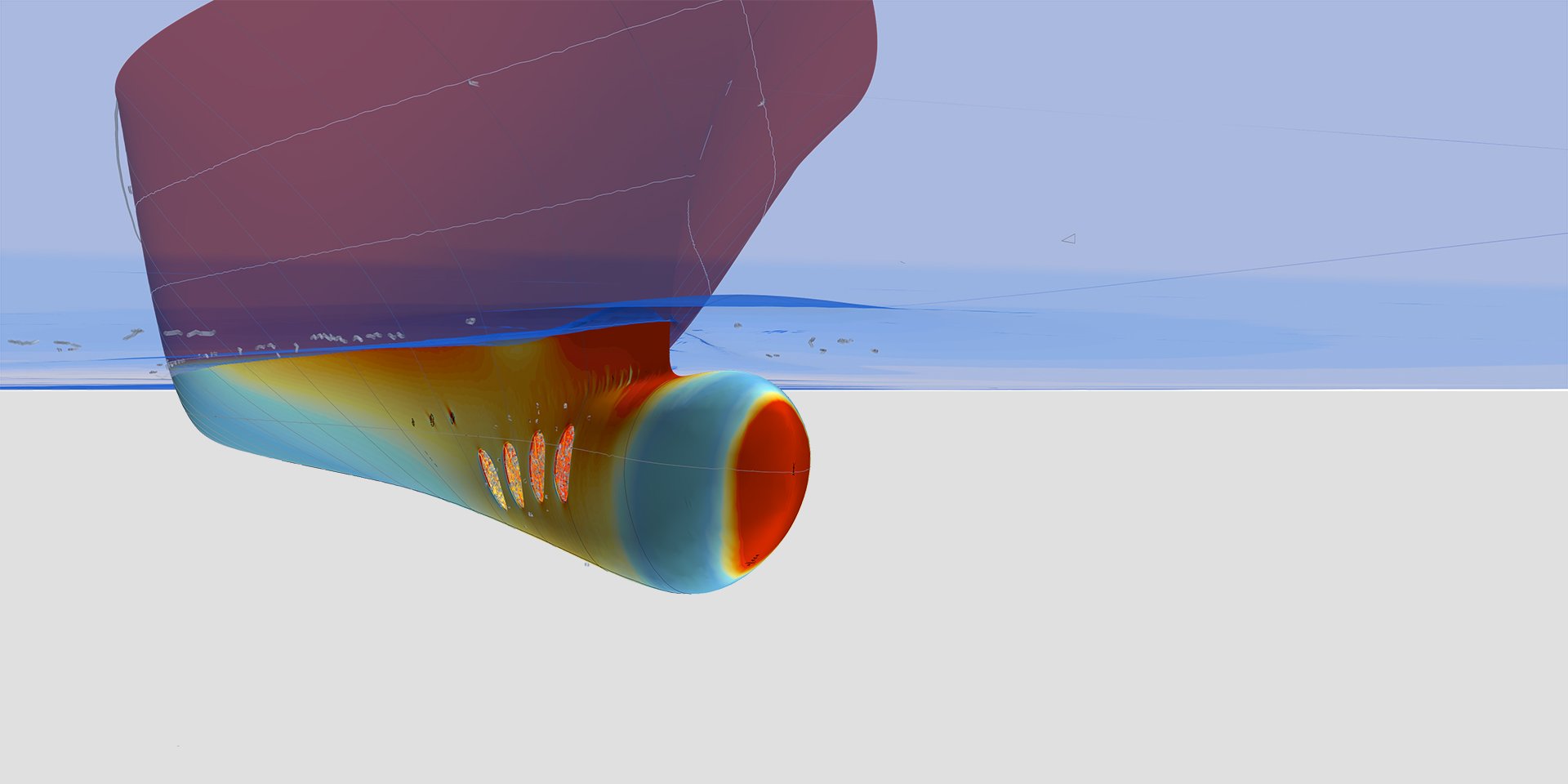

Operational Performance and Energy Efficiency Increase Through Hull Hydrodynamic Optimization

Most of ship energy is spent for moving ship from one place to another, and hydrodynamics is playing the most important role in that respect – as much as 50 – 95 % of all energy used in ship is spent for propulsion.

Highest potential for upgrading ship hydrodynamics into today’s level is naturally in older ships designed few years ago. Development in ship hull optimization has been rapid in present years thanks to increased computational power available and improved software quality. A major part of today’s ship hull, appendage and propulsion optimization can be done using computational fluid dynamics (CFD) simulations in big computer clusters, only the final solution would be necessary to test in a model basin.

Juha Tanttari, M.Sc (Mech. Eng.)

Juha Tanttari, M.Sc (Mech. Eng.)

Juha Tanttari has 20 years’ experience of working in fluid dynamics consulting. His experience covers a vast range of industrial segments including marine hydrodynamics and aerodynamics, project management and sales. Juha joined Process Flow in 1999, which was acquired by Elomatic in 2017. He currently holds the position of Lead Consulting Engineer, Technical Analysis.

juha.tanttari@elomatic.com